Fremragende | Baseret på 600+ anmeldelser

UltiMaker CPE - White - 750g

På lager

Leveringstid: 1-2 hverdage

Gratis fragt over 399 kr

Nem og billig retur

Kundeservice alle hverdage

Reasons to choose Ultimaker CPE Product designers use CPE to make extremely tough and dimensionally stable functional prototypes. Excellent chemical resistance Excellent toughness and dimensional stability Good interlayer adhesion, especially when using the front enclosure add-on Low levels of ultrafine particles (UFPs) and volatile organic compounds (VOCs) Ideal for short run manufacturing and functional prototypes Transparent option available.

Se sikkerhedsdatablad her

How to print with Ultimaker CPE

CPE (co-polyester) is a chemical resistant and relatively tough material that is widely used for functional prototyping and modeling. Here you will learn how to achieve the best print quality with Ultimaker CPE.

Ultimaker CPE can be printed on all Ultimaker 3D printers with a heated build plate as a single material. On the Ultimaker 3 it can also be printed in combination with PVA or another color of CPE.

Always use the latest version of Cura and make sure that your printer is updated with the latest firmware version to include the correct material profile for Ultimaker CPE.

Note: The information provided here applies to Ultimaker CPE. We cannot guarantee similar quality when using third-party filaments.

Recommended Settings

Temperatures

Ultimaker CPE requires a build plate temperature of 70 °C. Use the table below to find the recommended nozzle temperature and diameter for your Ultimaker to achieve the best print results.

Note: When using the Ultimaker 3, the nozzle and build plate temperature on the initial layer may be different due to the 'Print Temperature Initial Layer' and 'Build Plate Temperature Initial Layer' settings in Cura.

Cooling

The print cooling fan speed for Ultimaker CPE is different per printer and nozzle size to achieve the best quality. The fans are not fully on while printing to avoid layer bonding problems. For shorter layers, the print cooling fan speed is gradually increased to 100% to ensure optimal quality throughout the print.

Adhesion

Although Ultimaker CPE adheres well to the glass plate, it does tend to warp heavily. For optimal adhesion and glass plate protection using the correct adhesion methods is important.

Accessories

To minimize warping when printing with Ultimaker CPE, apply a thin layer of glue to the glass plate using the glue provided in the accessory box of your 3D printer. In addition to the adhesive properties, the glue serves as a protective layer for the glass plate. Not using the glue results in a high risk of chipping the glass plate when removing the print.

The Advanced 3D Printing Kit for the Ultimaker 2+ or Ultimaker 3 includes special adhesion sheets to ensure adhesion to the glass plate.

Cura build plate adhesion

In preconfigured Ultimaker CPE Cura profiles, the default build plate adhesion method is a brim. A brim is made of a few extra printed lines around the 3D print on the initial layer to improve adhesion and avoid warping.

Printing conditions

Ultimaker CPE filament prints reliably, therefore additional accessories such as the front enclosure included in the Advanced 3D Printing Kit are not necessary, unless you are printing large or thin-walled objects. In this case, the front enclosure will help avoid cracks in your 3D prints and provides a controlled print environment for more consistent and reliable results.

Health and safety

Ultimaker CPE emits low levels of gasses and particles when used in accordance with the temperatures in the table above. To ensure a comfortable and healthy environment, we recommend 3D printing in a well-ventilated area.

Tekniske specifikationer

Brand

UltiMaker

Filamenttype

CPE

Diameter

2.85 mm

Tolerance

±0.05 mm

Bruttovægt

1.0 kg

Nettovægt

750 g

Spolens materiale

Plast

EAN

8718836374791

Yderligere tekniske specifikationer

Forlængelse

8.2 %

Bøjningsstyrke

72.8 Mpa

Bøjningsmodul

1579 Mpa

Smelte flow indeks

13.2 g/10min

Massefylde

1.27 g/cm³

Biologisk Nedbrydeligt

Nej

På linket nedenfor, finder du en mappe med alt dokumentation for 3D printere, filamenter mv. Den vil løbende blive opdateret

Du kan få leveret din ordre til en valgfri GLS pakkeshop, privats- eller erhvervsadresse.

Vi leverer din ordre fragtfrit til en valgfri GLS pakkeshop, hvis du bestiller for over 399 kr.

Du har mulighed for at vælge afhentning i butik. Når du modtager en mail med at din ordre er færdig pakket, kan den afhentes indenfor vores åbningstider, som er mandag til torsdag 9-17.00 og fredag kl. 9-16.30 på vores adresse Amalienborgvej 57 i Nørresundby.

Vil du vide mere om vores returregler, læs dem her

Vi ser frem til din ordre 😍

Kundeservice

Email: info@3deksperten.dk

Telefon: +45 30 20 22 17

Mandag til torsdag: 9:00 - 17:00

Fredag: 9:00 - 16:30

UltiMaker CPE - White - 750g

Du kiggede tidligere på

Se hvad vores kunder har skabt

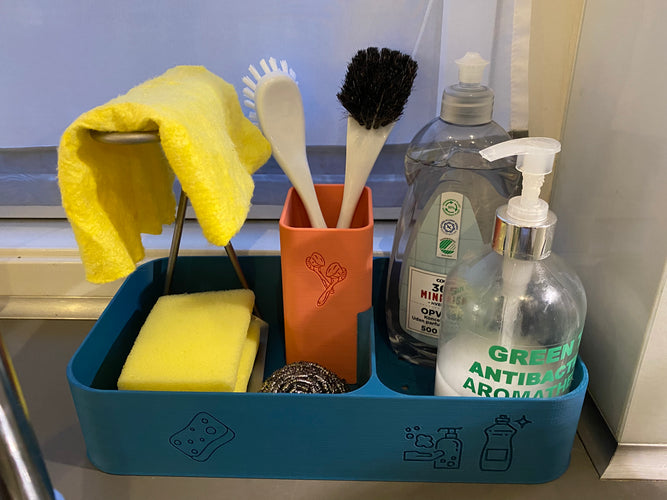

3Dkat

Kitchen organizer. PLA filament

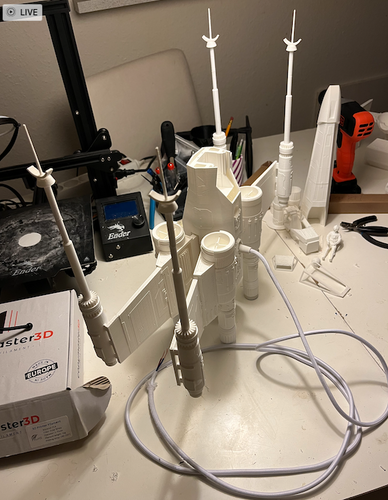

Alexander fra Birkerød

X-Wing fighter - med tubelys som motor. PLA Filament.

Alexander fra Birkerød

X-Wing fighter - med tubelys som motor. PLA filament.

Allan

Projekt Pokemon 151. PLA filament.

Allan

Projekt Pokemon 151. PLA filament.

Benjamin fra Pandrup

Bugs bunny - 1 meter og 25cm høj. PLA filament.

Brian

96 lysfiber holdere med fingerskrue til en rum udstilling

Brian

Brian

PLA filament.

Carl fra Svenstrup J

To figurer med de kendte logoer Louis Vuitton og stussy. PLA filament.

Casper fra Nordjylland

En holder til min mobile elbilslader, hvor den øverste del kan tages af, således man kan tage laderen med sig ved behov. PLA Filament.

Christian

Holger Danske

Daniel fra Silkeborg

Proton pack Fra Ghostbusters!(Før den bliver malet). Printed i PLA.

Flemming

En nomer

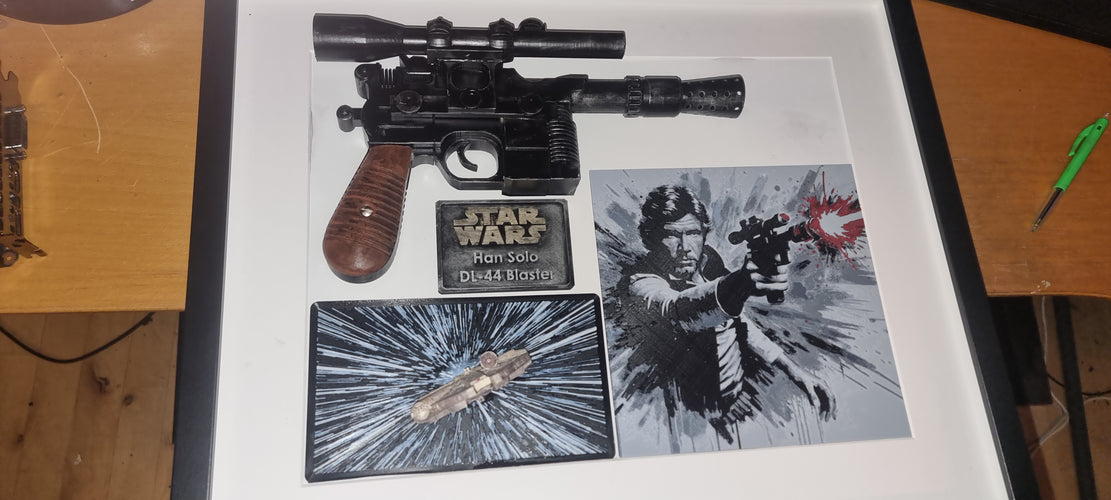

Frank

Star wars. Han solo blaster, en gave til min far i farsdag gave.

Freddy

Det er flaskeholdere jeg selv har printet i PLA filament

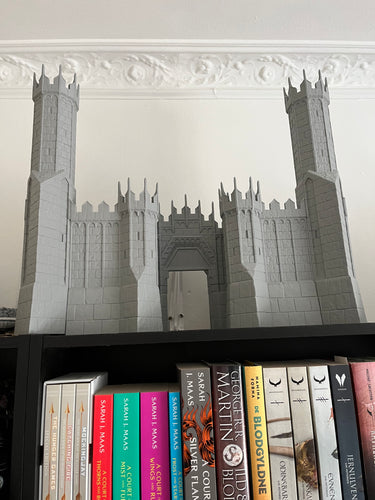

Glen

Pc kabinet designet som middelalder kro

Helge

Ukulele

Jesper fra Kerteminde

Beholder til Silica Gel Beads i 3DE Premium ABS. Begge dele printet på en Bambu P1S.

John

Japansk havelampe

Jonas

3D printed drage som lige er strikket.

Jonas WP

DM screen

Jule fra Aalborg

Skuffe indsatser til at huse de mange skriveredskaber jeg ejer. Nemme at tage med til arbejdsbordet og gør det nemt at rydde op igen bagefter. Eget Design. PLa Filament.

Kasper

Funktionel elguitar Les Paul-style med ST hardware

Kasper fra Tylstrup

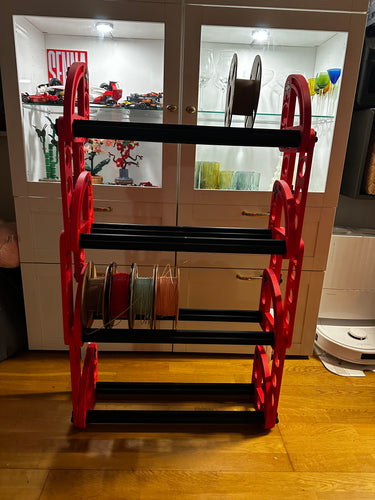

Filament reol, i kæmpestort LEGO teknik. PLA filament.

Kasper fra Tylstrup

En bordlampe. PLA filament

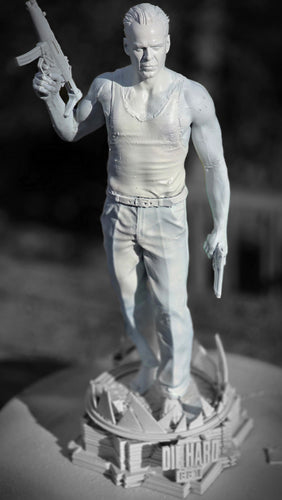

Kim

En figur af Bruce Willis fra Die Hard

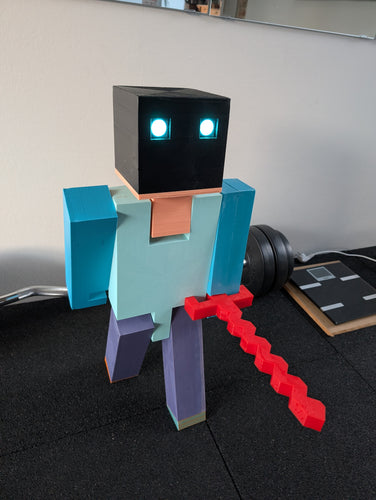

Kim fra Nyborg

Egen fortolkning af en Minecraft Steve en meter høj 4 Kg lys i øjnene. PLA filament.

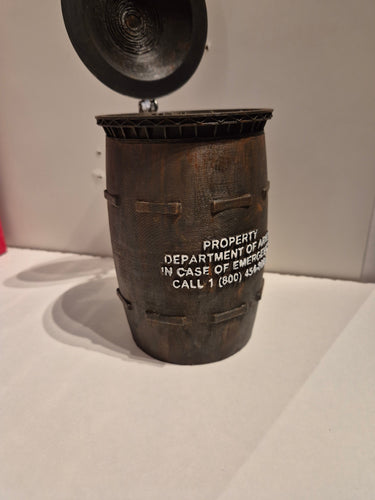

Kresten fra København

Tønden fra "The Return of the living dead" som indeholder zombien "The Tarman". PLA filament.

Kresten fra København

Tønden fra "The Return of the living dead" som indeholder zombien "The Tarman". PLA Filament.

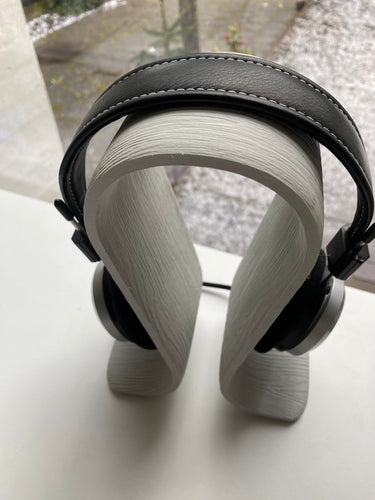

Louis

En headset holder

Malthe

Har printet en daredevil maske med røde led øjne der kan lyse op, og er igen med at lave daredevils Billy clubs som virker

Marianne

Kortholder samt boks til uno kort

Mette fra Esbjerg

Mit første design. Har fået navnet Nulpkt. Jeg er stolt og jeg syntes det er faktisk det er okay. Jeg har designet til mellemstore fugle. Diameter på 32 mm hul, så musvitter kan bruge det. Printet i PLA og Carbon Fiber PLA filament.

Michael

Michael

Vægholder til Wilfa håndmixer. PLA og PETG filament

Michael

Værktøjsholder til Um S5. Pla og PETG Filament

Michael

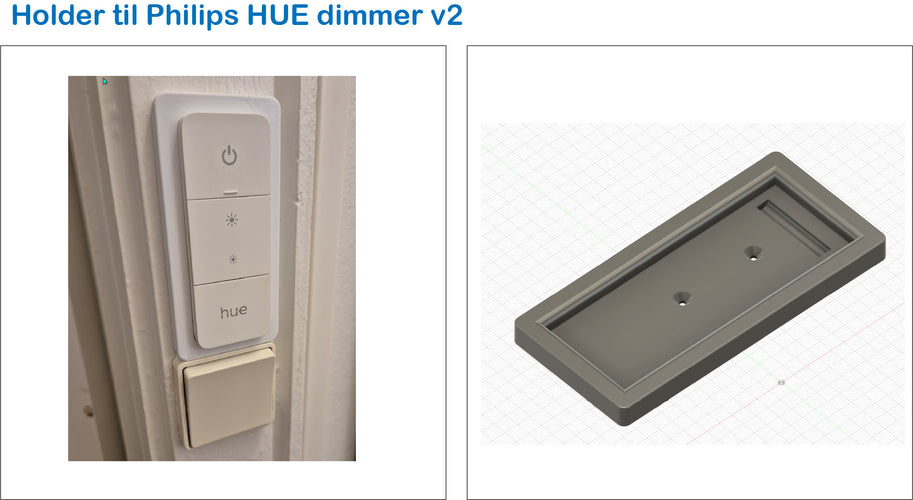

Holder til Hue belysning. PLA og PETG Filament

Michael

Click-on hjørner til tablet. PLA og PETG Filament

Sendes inden for 1-2 hverdage

Sendes inden for 1-2 hverdage

Gratis fragt over 399 kr. til pakkeshop

Gratis fragt over 399 kr. til pakkeshop

40.000+ tilfredse kunder

40.000+ tilfredse kunder

EAN betaling

EAN betaling